Wood framing is the structural backbone of most homes and light commercial buildings in North America. Yet most articles oversimplify it, confuse materials with systems, or drown readers in fluff. This guide does the opposite.

Here, you’ll get a clear, technically accurate breakdown of the types of wood framing, the wood frame construction types used today, what type of wood is used in framing a house, and how to choose the right system for performance, cost, and longevity—especially in the Pacific Northwest.

If you’re a homeowner, developer, or builder who wants real answers instead of recycled content, you’re in the right place.

Types of Wood Framing for Custom Homes & Construction Projects

Wood framing choices directly affect:

- Structural integrity

- Energy efficiency

- Fire performance

- Long-term maintenance costs

Choosing the wrong system or material doesn’t just cost money—it creates risk.

Let’s get precise!

What Is Wood Framing and Why Does It Matter?

Wood framing is a construction method where dimensional lumber or engineered wood forms the load-bearing skeleton of a building—supporting floors, walls, and roofs.

Key framing components include:

- Studs (walls)

- Joists (floors)

- Rafters or trusses (roofs)

- Beams and headers (load transfer)

The framing system determines how loads move to the foundation, how well the structure resists wind and seismic forces, and how easily insulation and utilities integrate.

Bottom line: framing is not a commodity decision—it’s a systems decision.

Types of Wood Framing Systems

There are three primary types of wood framing systems used in construction. Everything else is a variation or enhancement of these.

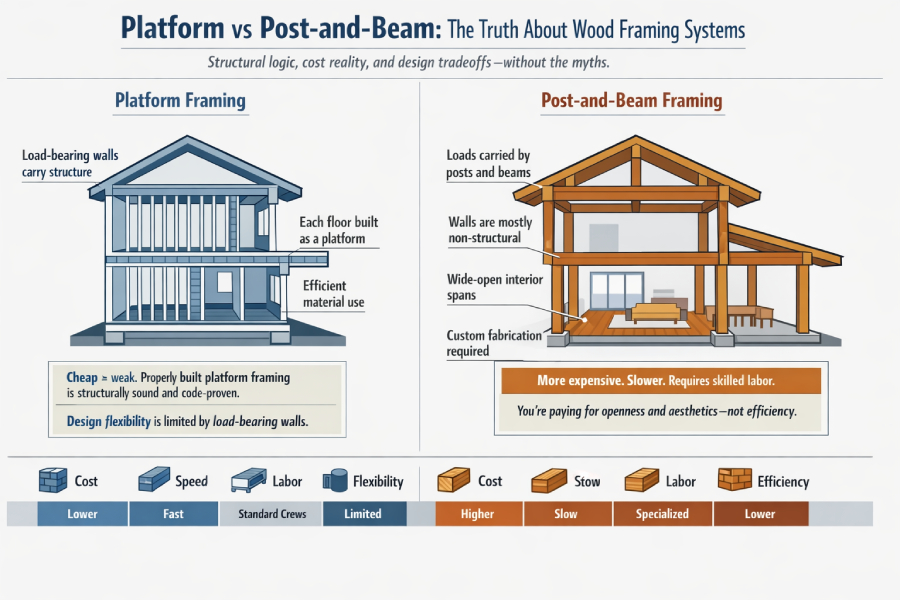

Platform Framing (Modern Standard)

Platform framing—often called “stick framing”—is the dominant wood frame construction type in residential building today.

How it works

- Each floor is built as a separate platform

- Walls sit on top of the floor deck

- Built-in fire stopping at every level

Why it dominates

- Code-compliant and inspector-friendly

- Uses standard-length lumber

- Excellent for insulation and air sealing

- Lower labor costs than alternatives

Best use cases

- Single-family homes

- Townhomes

- Low- to mid-rise residential buildings

Reality check: If you’re building a house today, platform framing is almost always the baseline unless design demands otherwise.

Balloon Framing (Historic, Not Obsolete—But Rare)

Balloon framing uses continuous studs running from foundation to roof—a method common in the 1800s and early 1900s.

Advantages

- Allows tall wall cavities

- Open interior layouts

Serious drawbacks

- Fire spreads rapidly through wall cavities

- Difficult to retrofit to modern codes

- Requires long, hard-to-source lumber

When it matters today

- Renovations of historic homes

- Fire-blocking upgrades

- Structural evaluations during inspections

Hard truth: balloon framing is not chosen—it’s inherited.

Post-and-Beam Framing (Heavy Timber)

Post-and-beam framing uses large vertical posts and horizontal beams to carry loads, often leaving wood exposed.

Strengths

- Wide open interior spans

- Architectural character

- Exceptional durability

Trade-offs

- Higher material and labor costs

- Requires skilled craftsmanship

- Often combined with infill framing

Ideal for

- Custom homes

- Barns, lodges, churches

- Design-forward residential projects

Common Types of Wood Used in Framing

When people ask “what type of wood is used for framing?” the answer depends on availability, climate, and structural demands.

Softwoods Used for Framing Walls

Douglas Fir

- High strength-to-weight ratio

- Excellent dimensional stability

- Ideal for beams, joists, and stud

Southern Yellow Pine

- Dense and strong

- Common in pressure-treated applications

- Excellent load-bearing capacity

Hem-Fir

- Cost-effective

- Moderate strength

- Common in wall framing

SPF (Spruce-Pine-Fir)

- Lightweight and affordable

- Easy to work with

- Widely used in residential framing

These are the most common answers to what type of wood is used in framing walls.

Engineered Wood Products

Engineered wood improves consistency and span capacity.

Common products

- Glulam: laminated beams for long spans

- LVL / PSL: headers and beams

- CLT: mass timber panels for floors and walls

Engineered wood doesn’t replace framing systems—it enhances them.

Choosing the Right Wood for Your Project

In regions like Seattle, Bellevue, and Tacoma, moisture management and seismic resistance matter more than average.

Key decision factors

- Climate exposure

- Local building codes

- Budget constraints

- Span requirements

- Fire-resistance goals

Pro insight: In the Pacific Northwest, kiln-dried lumber and proper vapor control matter more than species choice alone.

Advanced Framing Techniques

Optimized Value Engineering (OVE)

OVE framing:

- Reduces lumber use

- Increases insulation space

- Improves energy efficiency

Done correctly, it lowers costs without sacrificing strength.

Prefabrication & Modular Framing

Benefits:

- Faster build times

- Higher quality control

- Reduced waste

Fire-Resistant Framing

Modern codes increasingly require:

- Fire-treated lumber

- Gypsum-based assemblies

- Compartmentalized framing

Common Challenges in Wood Framing and Solutions

Moisture

- Use kiln-dried lumber

- Install vapor barriers correctly

Warping

- Store materials properly

- Use engineered products where needed

Load Distribution

- Proper beam sizing

- Engineer long spans

Cost Considerations for Different Framing Types

Relative cost comparison

- Platform framing: lowest upfront cost

- Balloon framing: high retrofit cost

- Post-and-beam: higher initial cost, long lifespan

Typical framing cost drivers

- Labor rates

- Lumber market volatility

- Complexity of design

Strategic insight: spending more on framing often saves money over the building’s life cycle.

Why Choose Infinity Construction for Your Wood Framing Projects?

Infinity Construction brings:

- Deep expertise in types of wood framing

- Local code mastery across Washington

- Precision execution for custom homes

- Proven material selection strategies

This isn’t cookie-cutter framing—it’s engineered, intentional construction.

Conclusion

Wood framing isn’t just about wood—it’s about systems, materials, climate, and execution working together.

Understanding the types of wood framing, and what type of wood is used in framing a house allows you to:

- Reduce long-term risk

- Improve performance

- Control costs intelligently

Next step: Talk with Infinity Construction to frame your project correctly—before mistakes get buried behind drywall.