Choosing between wood vs steel framing is one of the most consequential decisions in custom home construction. The frame is the structural backbone of the house—it determines how the building performs, how easily it can be modified, how much it costs to build, and how it ages over time.

Steel framing has gained visibility in recent years due to durability claims, fire resistance, and commercial construction trends. But when you strip away marketing narratives and look at real-world residential construction, wood framing remains the superior choice for most custom homes—especially in regions like Seattle, Bellevue, and Tacoma.

This guide breaks down wood framing vs steel framing honestly and in depth—covering cost, durability, sustainability, performance, and constructability—so homeowners can make informed decisions without sales-driven bias.

What Is Wood Framing and Why Is It Ideal for Custom Homes?

Wood framing—often called stick framing—uses dimensional lumber or engineered wood products to create wall, floor, and roof assemblies. It has been the dominant residential construction method in North America for over a century, and for good reason.

For custom homes, wood framing excels because it balances structural performance, affordability, adaptability, and energy efficiency in a way steel framing simply doesn’t for low-rise residential projects.

In Pacific Northwest climates, wood framing performs particularly well:

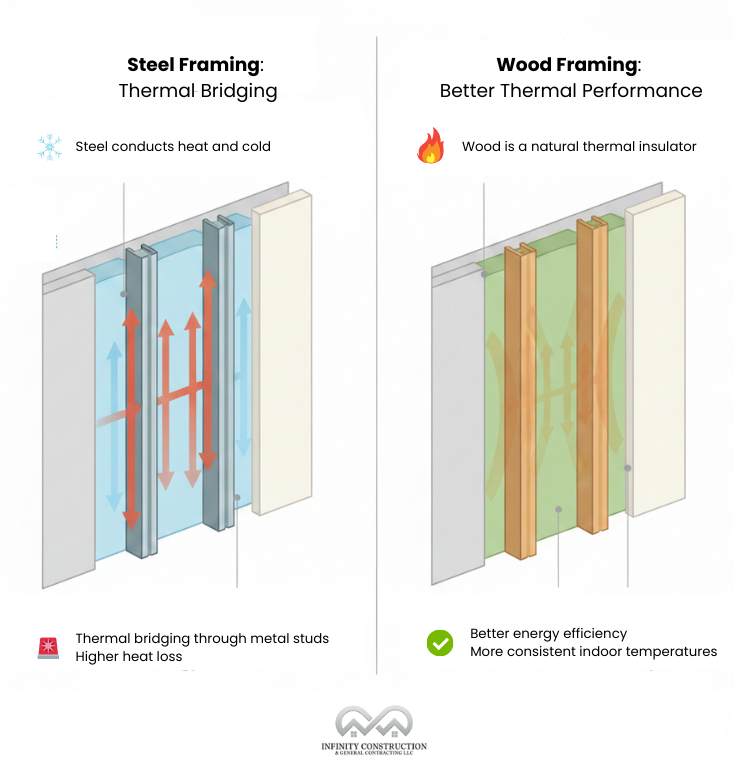

- Wood is a natural thermal insulator, reducing heat loss.

- Builders can easily integrate moisture-management strategies like rainscreens and ventilated wall assemblies.

- Engineered wood products (LVL, glulam, CLT) improve strength and dimensional stability while retaining wood’s flexibility.

Wood framing isn’t just traditional—it’s optimized for residential construction.

Key Benefits of Wood Framing for Custom Homes

Affordability

One of the most searched questions in this debate is: is steel framing cheaper than wood?

For custom homes, the answer is usually no.

Wood framing typically costs less upfront due to:

- Lower material prices (especially when markets stabilize)

- Faster installation

- Broader contractor availability

- Standard fasteners and tools

Typical framing cost comparison (custom home averages):

- Wood framing: Lower material + lower labor costs

- Steel framing: Higher material costs + higher labor rates + added insulation detailing

While steel proponents argue long-term savings, those claims often ignore:

- Increased insulation costs

- More complex detailing

- Higher modification and repair expenses

In practice, steel framing vs wood framing cost favors wood for residential projects.

Design Flexibility

Custom homes change during construction—layouts evolve, openings shift, details get refined. Wood framing handles this reality better than steel.

Wood allows:

- On-site modifications without specialized equipment

- Easier electrical and plumbing changes

- Faster adaptation to client requests

Steel framing is precise but rigid. Once assembled, changes are slower, costlier, and require experienced metal framers. For truly custom homes, flexibility matters—and wood wins decisively.

Sustainability

Wood framing is one of the most environmentally responsible structural systems when sourced correctly.

Key sustainability advantages:

- Wood is renewable

- Trees sequester carbon during growth

- Wood products require less energy to manufacture than steel

- Sustainably harvested lumber supports long-term forest health

Steel is recyclable, but steel production is energy-intensive and carbon-heavy. From a lifecycle perspective, wood framing generally has a lower embodied carbon footprint, especially in residential construction.

Comparing Wood Framing and Steel Framing for Custom Homes

Cost Comparison

When comparing steel framing vs wood framing, cost must be evaluated holistically—not just materials.

Wood framing costs less because:

- Labor is faster and more available

- Fewer specialized fasteners are required

- Energy-code compliance is simpler

- Repairs are straightforward

Steel framing often requires:

- Continuous exterior insulation to address thermal bridging

- Specialized fasteners and tools

- Trades familiar with metal framing

Bottom line: wood framing is more cost-effective for custom homes, both initially and during ownership.

Durability and Maintenance

Steel framing advantages:

- Non-combustible

- Resistant to termites

- Dimensionally stable

Wood framing advantages:

- Proven longevity with proper detailing

- Easier repairs

- Better tolerance of minor construction variability

Modern wood framing is not fragile. Pressure-treated lumber, engineered wood products, and proper moisture management result in structures that last generations.

Maintenance reality:

- Steel requires corrosion protection in damp or coastal environments

- Wood requires moisture control—but repairs are simpler and cheaper

Durability is about system performance, not just material strength.

Environmental Impact

Wood framing:

- Renewable

- Carbon-storing

- Lower embodied energy

- Regionally sourced

Steel framing:

- Fully recyclable

- Higher manufacturing emissions

- Greater transportation impacts

For residential sustainability goals, wood framing aligns better with green building standards and long-term environmental responsibility.

Is Steel Framing Better Than Wood?

Steel’s Strength

Steel is undeniably strong—and that strength matters in:

- Commercial buildings

- Multi-story structures

- Large-span applications

- Industrial facilities

For those use cases, steel is often the right choice.

But residential homes rarely fail because studs aren’t strong enough. Failures occur due to:

- Poor connections

- Inadequate shear walls

- Moisture intrusion

- Envelope design flaws

Steel’s raw strength offers limited advantage in single-family homes.

Wood Framing’s Suitability for Residential Projects

Wood framing remains the ideal solution for custom homes because it:

- Meets residential structural demands efficiently

- Supports energy-efficient wall assemblies

- Is easier to source locally

- Aligns with contractor expertise

- Keeps costs predictable

In residential markets like Seattle, Bellevue, and Tacoma—where moisture control, insulation performance, and customization matter—wood framing consistently outperforms steel in real-world outcomes.

Conclusion: Why Wood Framing Is the Best Choice for Your Custom Home

When evaluating wood vs steel framing, it’s tempting to focus on material claims alone. But custom homes demand more than strength—they require flexibility, affordability, energy efficiency, and long-term value.

Wood framing delivers all of that.

It’s:

- More cost-effective

- Easier to modify

- Better insulated

- More sustainable

- Backed by a deep residential construction ecosystem

Steel framing has its place—but for most custom homes, wood remains the smarter, more practical choice. If you’re planning a custom home or addition, contact Infinity Construction to discuss how expert wood framing can turn your vision into a durable, high-performance home built for the Pacific Northwest.